Sustainable & Ethical Supply Chains

At Scotch & Soda, we design our garments with great care and an eye for detail. That same love and attention can also be found in the way we produce our garments. Creating responsible fashion starts with the materials and the people and producers who create the finished garment. It's a complex process in which expertise and craftmanship come together through a series of steps, known as the supply chain. We are precise in selecting who we work with, and so we only operate with factories and manufacturers where stringent environmental policies and good working conditions are ensured. Scotch & Soda takes pride in these long-term relationships, some of which have existed for over 20 years. As trusted business partners, they are fundamental to the unique Scotch & Soda design and production process.

SOCIAL RESPONSIBILITY

We aim to bring more unity in the world, to create a fair working environment for each and every individual. We strive to advocate inclusiveness both internally and externally.

In 2013, we became a member of the Amfori Business Social Compliance Initiative (Amfori BSCI), the leading global business association for open and sustainable trade. Amfori is a business-driven initiative for companies committed to improving working conditions in the global supply chain. Their code aligns with international frameworks concerning human rights and labour standards, including the Declaration of Human Rights, the Children's Rights and Business Principles, UN guiding Principles for Business and Human Rights and OECD guidelines, as well as the conventions and recommendations of the International Labour Organisations (ILO), which are relevant to improving working conditions in the supply chain.

Click here for our annual Modern Slavery Act statement, financial year ended May 2020.

In 2013, we became a member of the Amfori Business Social Compliance Initiative (Amfori BSCI), the leading global business association for open and sustainable trade. Amfori is a business-driven initiative for companies committed to improving working conditions in the global supply chain. Their code aligns with international frameworks concerning human rights and labour standards, including the Declaration of Human Rights, the Children's Rights and Business Principles, UN guiding Principles for Business and Human Rights and OECD guidelines, as well as the conventions and recommendations of the International Labour Organisations (ILO), which are relevant to improving working conditions in the supply chain.

Click here for our annual Modern Slavery Act statement, financial year ended May 2020.

ABOUT THE AMORFI-BSCI CODE OF CONDUCT

The Amfori-BSCI program unites more than 2,000 companies worldwide around a common code of conduct and supports them with a step-by-step development focused system. We fully endorse and live by each of the values and principles set out in this code. The factories we work with are regularly audited by independent and certified (SAAS) audit firms, in accordance with the Amfori BSCI requirements and for compliance with this code. If it becomes evident that a factory does not fully comply with the Amfori BSCI requirements, we insist upon the implementation of a remediation plan. In doing so, we monitor all factories every year, improving – if necessary – working conditions in Scotch & Soda production factories.

Read more about the Amfori-BSCI code of conduct here.

Read more about the Amfori-BSCI code of conduct here.

RESTRICTED SUBSTANCE LIST

We have a list of over 100 chemicals (including chemical finishes and procedures) that we do not use in the creation of our collections, documented in the Scotch & Soda Restricted Substance List (RSL). All our suppliers commit to and comply with the RSL list, which ensures that the legislation surrounding the proper use of chemicals and substances is upheld. To ensure compliance, our products are regularly checked by third-party certified testing laboratories.

TRANSPARANCY

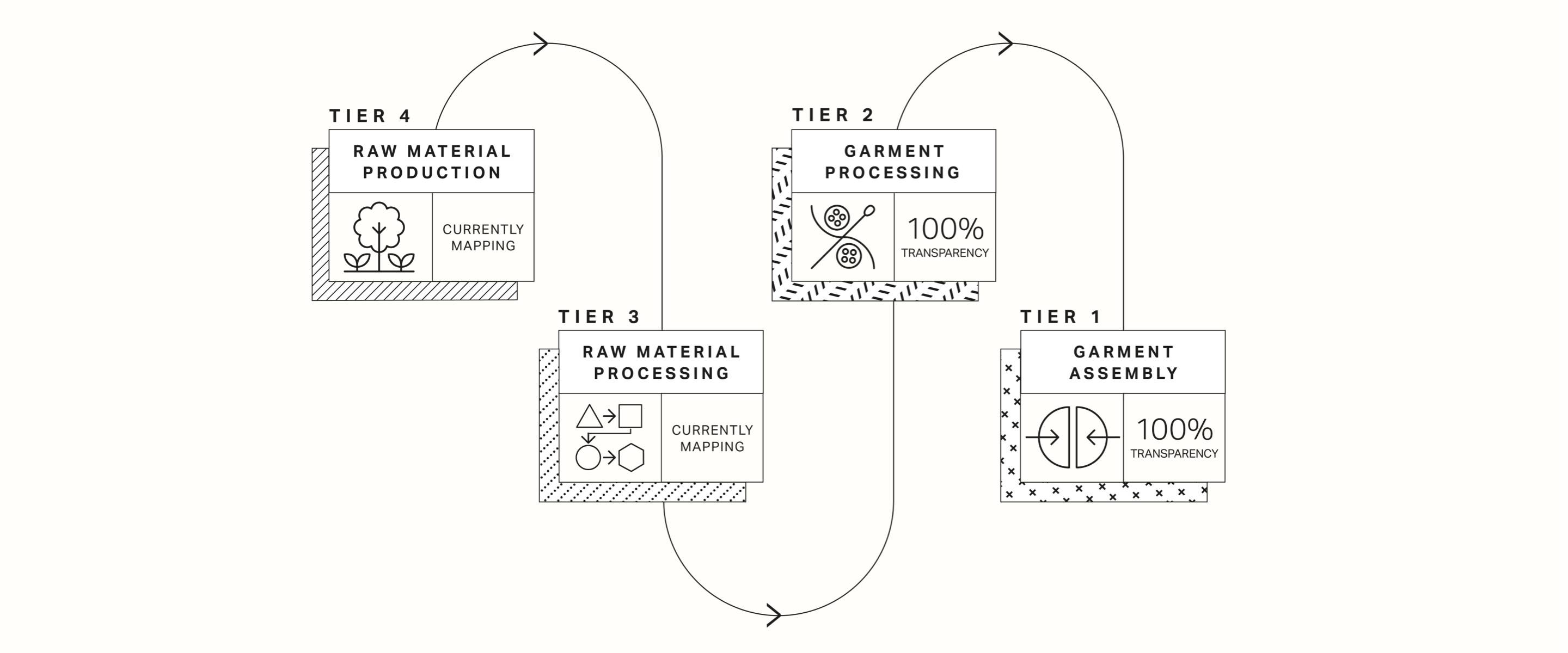

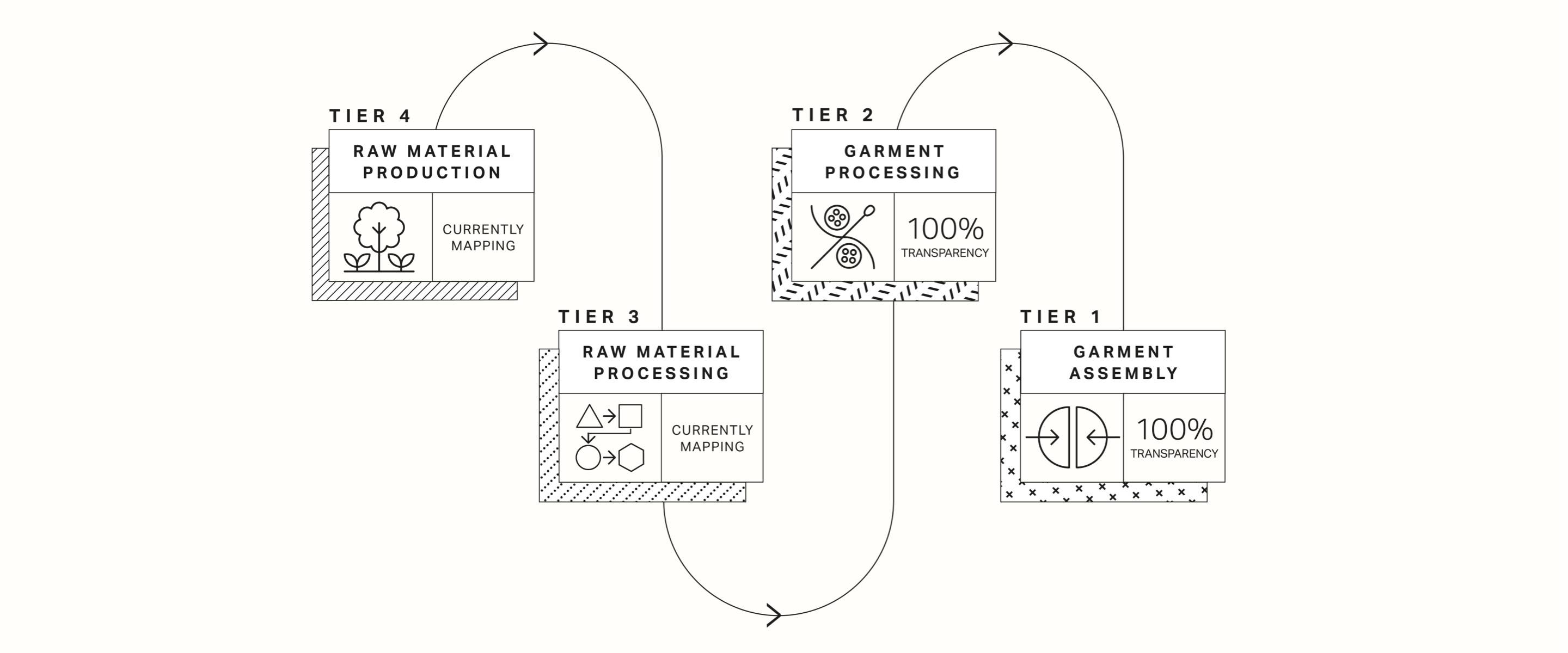

The path to creating a finished garment is a complex process, which can be broken up into four tiers. Each one represents a different part of the process. Tier one and tier two include the factories and manufacturers responsible for the production and finishing of materials, as well as the assembly of the final garment. Tier three and four are the farms, growers of the raw materials and the factories that process them. From the raw materials to the finished garment, our end goal is to be completely transparent about where and who manufactures your clothes. It's a complex process but we've made progress by mapping all tier one and tier two suppliers, and they have signed the Amfori BSCI Code of Conduct. We are working in partnership with each supplier to achieve Amfori/BSCI compliance by July 2021. We are also in the process of documenting tier three and tier four of the supply chain, to provide transparency all the way back to the raw materials. The process of mapping allows us to measure our social and environmental impact and set effective targets for improvement.

WHERE WE PRODUCE

We produce in 12 countries, working with a number of factories in each area. Our main production countries are China, India and Turkey, as visualized on this map in which the percentage represents the share of factories within our production system.

A full list of our tier one and tier two suppliers can be downloaded here.